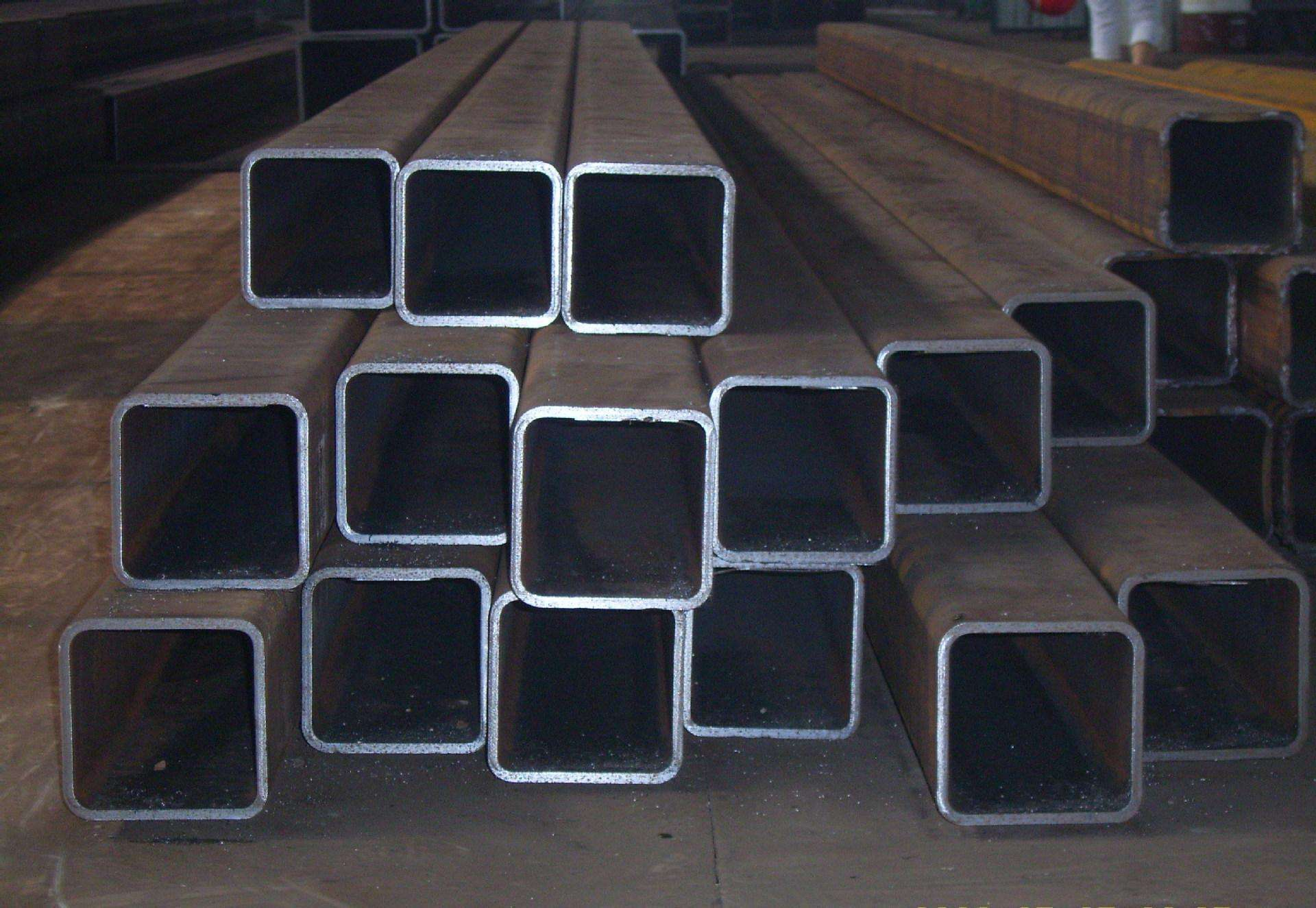

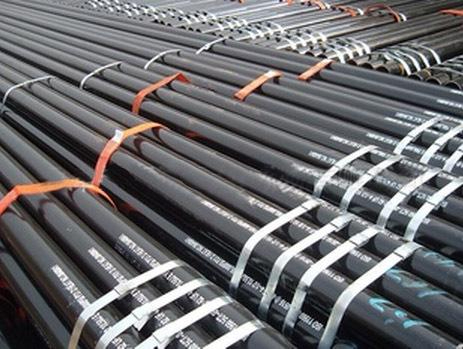

首先(xiān)要看nd鋼管的表麵。觀察(chá)亮度和(hé)表麵有無漏焊和脫(tuō)皮等表麵問題。好的nd鋼管表麵色澤光亮,一(yī)般情(qíng)況下不(bú)會生鏽。 第二點就是看材質。化(huà)學成分是nd鋼管(guǎn)的(de)基礎。檢查化(huà)學成分是否達標是nd鋼管很重要的檢(jiǎn)查方式。還有就是檢查是否精煉爐的材料。 第三點就是要看做工。圓管的圓度、方管的方度、表(biǎo)麵的處理、nd鋼管兩端的處理、還有很重要的一點就是整隻鋼管的平直度。

First of all, we should look at the surface of ND steel pipe. Observe the brightness and surface problems such as welding leakage and peeling. A good ND steel pipe has a bright surface and will not rust in general. The second point is to look at the material. Chemical composition is the basis of ND steel pipe. Checking whether the chemical composition is up to the standard is an important inspection method for ND steel pipes. The other is to check whether the material of the refining furnace is available. The third point is to look at the workmanship. Roundness of circular pipe, squareness of square pipe, surface treatment, treatment of both ends of ND steel pipe, and a very important point is the flatness of the whole steel pipe.

最後,好的nd鋼(gāng)管廠家擁有好的管理層、好的操作工、好的(de)製度(dù)、有一定的知名度和信譽度,產出來的產品(pǐn)自然也能滿足客戶的(de)高端要求。而一(yī)些小的或者不正規的鋼管廠家生產出來(lái)nd鋼管不僅在外觀上與好的nd鋼(gāng)管有差距,其堅硬程度、韌性,也有很大的差距。

Finally, a good ND steel pipe manufacturer has good management, good operators, good system, a certain degree of popularity and credibility, and the products produced can naturally meet the high-end requirements of customers. And some small or irregular steel pipe manufacturers produced ND steel pipe not only in appearance and good ND steel pipe has a gap, its hardness, toughness, but also a big gap.

nd鋼管良好的溫度控製試管冶金過程(chéng)的順利(lì)完成,如氧化脫磷的保證不僅要求高,高堿(jiǎn)度渣,還需要具有良(liáng)好的耐高溫配合。這是強調理性的早期脫磷。因為這時溫度低有利於關盤;在氧(yǎng)化精煉期間,造成活(huó)性炭氧沸(fèi)騰,要求具有高溫(wēn)(大於1550?);冶金工程使(shǐ)爐侯處理和周圍澆(jiāo)鑄(zhù)正常為,根據使用的不同的(de)過程中(zhōng),要求(qiú)爐早鋼液具有過熱度的必須的,以補(bǔ)償(cháng)出鋼過程中,與爐輸送(sòng),處理的精煉和(hé)鋼液外溫度的損失。

The smooth completion of the metallurgical process of ND steel tube with good temperature control, such as the guarantee of oxidative dephosphorization, requires not only high requirements, high basicity slag, but also good high temperature resistance cooperation. This is to emphasize rational early dephosphorization. Because the low temperature is beneficial to shut down at this time; during the oxidation refining period, the activated carbon oxygen boiling is caused, requiring a high temperature (greater than 1550); metallurgical engineering makes the furnace processing and surrounding casting normal; according to the different process used, it is necessary to require the furnace early molten steel to have superheat, in order to compensate for the loss of refining and molten steel temperature in the process of tapping, conveying with the furnace, processing.