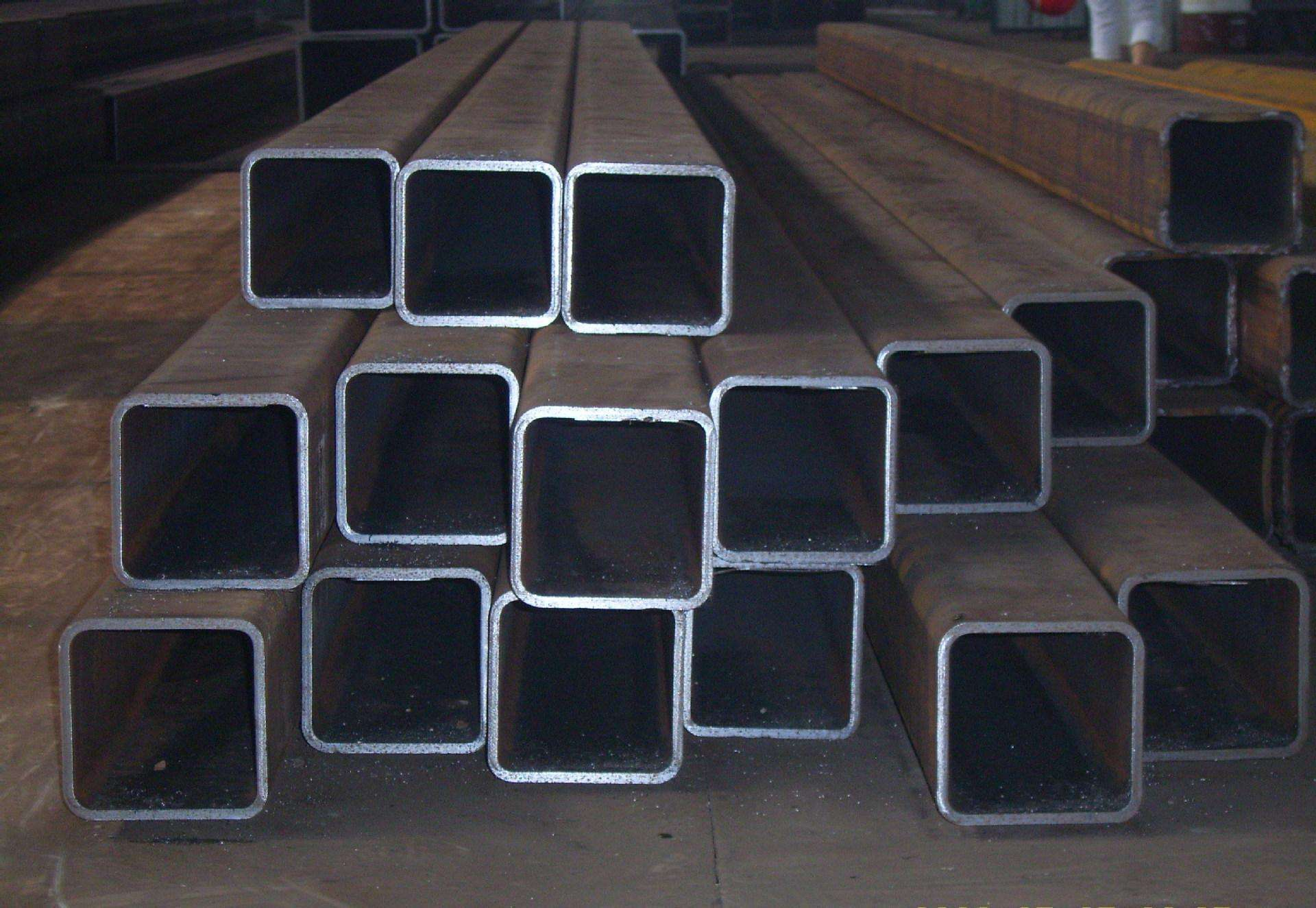

有時方管坯會出現分(fèn)層問題,從(cóng)而導致探傷不合。要(yào)預防這一缺陷(xiàn),我們可以采取以(yǐ)下三點處理措施:(一)優化緩冷時間:優化方管板坯的(de)緩冷工藝,主要針對堆(duī)垛溫度和堆垛持續時間。軋製鋼(gāng)板厚度不大於80mm鋼板(bǎn)熱矯直後,在冷(lěng)床停(tíng)留時間不得超過5min。厚度大於(yú)80mm鋼板可適當延長至10min,確保鋼板成垛前溫度控製(zhì)在500℃以上。鋼板厚度不大於50mm鋼板(bǎn)緩(huǎn)冷時間在(zài)12h;厚度大於50mm的鋼板緩冷時間24h,嚴禁提前拆垛精整(zhěng)。

Sometimes the stratification of square billet will occur, which will lead to incompatibility of flaw detection. To prevent this defect, we can take the following three measures: (1) Optimizing slow cooling time: optimizing slow cooling process of tube slab, mainly for stacking temperature and stacking duration. After hot straightening, the residence time in the cold bed should not exceed 5 minutes for the rolled steel plate whose thickness is not more than 80 mm. Thickness of steel plate over 80 mm can be appropriately extended to 10 minutes to ensure that the temperature of steel plate before stacking is controlled above 500 C. The slow cooling time of steel plate with thickness less than 50 mm is 12 hours; the slow cooling time of steel plate with thickness greater than 50 mm is 24 hours. It is strictly forbidden to disassemble and stack in advance.

(二)優化控製(zhì)冷卻

(2) Optimizing Controlled Cooling 方管板坯出現貝氏體一般是由於冷速過快造成的。當冷(lěng)卻速度降低至3-5℃/s時,鋼板心部偏析帶不再出(chū)現貝氏體組織,形成常規的珠光體組(zǔ)織(zhī)。控製冷卻(què)優化後,板坯心部偏析帶組織應力明顯減少,因組織應力產生的微裂紋得到大大改善。

Bainite in square tube slab is usually caused by too fast cooling rate. When the cooling rate is reduced to 3-5 C/s, the bainite structure is no longer present in the segregation zone of the steel plate core, and the conventional pearlite structure is formed. After controlled cooling optimization, the microstructural stress of segregation zone in the center of slab decreases obviously, and the microcracks caused by microstructural stress are greatly improved.

(三)集中裝爐製度

(3) Centralized charging system

在實(shí)際生產中軋製鋼板的長及(jí)寬相差較大,在鋼板緩(huǎn)冷時存在堆垛不整齊的情(qíng)況,導致超寬板邊部探傷檢驗不合格或是超長(zhǎng)板頭(tóu)部探傷檢驗不(bú)合格。通過建立集中裝爐製度,安排軋製鋼板長、寬相(xiàng)近的合同集中裝爐(lú),保證後續鋼板堆垛的整(zhěng)齊(qí)。必要時對方管板坯周(zhōu)邊采用石棉布包裹,加強保溫效果(guǒ)。

In actual production, the length and width of rolled steel plate are quite different. When the steel plate is slowly cooled, there is irregular stacking, which results in unqualified edge inspection or head inspection of ultra-wide plate. By establishing the centralized charging system, arranging the contract centralized charging of rolling steel plate with similar length and width to ensure the orderliness of subsequent stacking of steel plate. When necessary, asbestos cloth is used to wrap around the square tube slab to enhance the insulation effect.