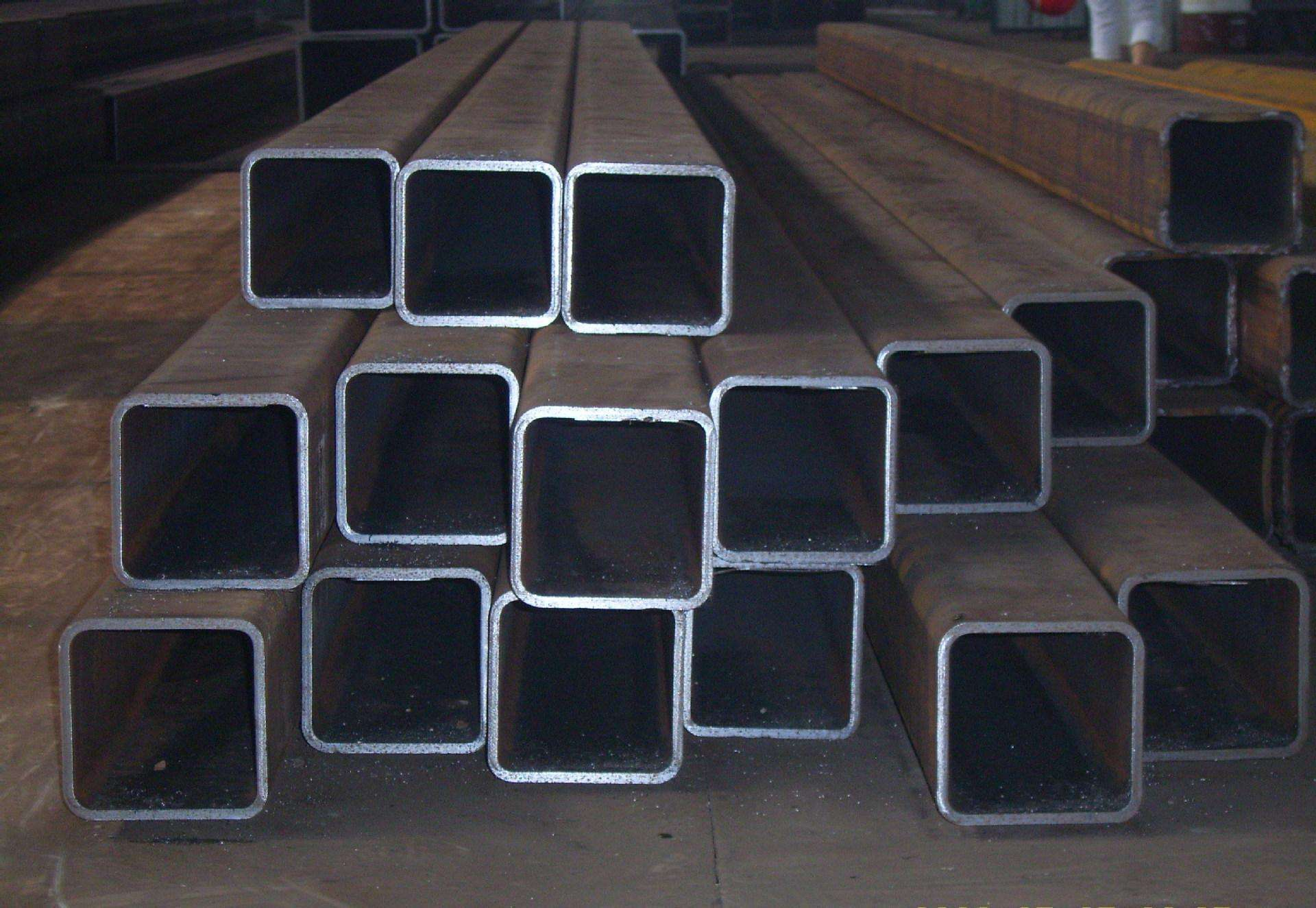

方管表麵缺陷的檢測方法,主要有以下(xià)五種:一電(diàn)渦流檢測.電渦流檢測有多種形式,常用的有常規渦流檢(jiǎn)測、遠場渦流檢測、多頻渦流檢測和脈衝渦流(liú)檢測等,利用電渦流傳感器對金屬進(jìn)行感應,方管表麵不同缺陷類型和形狀將產生不同類型的信號。其優點(diǎn)是(shì)檢測精度高、探測靈敏度高(gāo),檢測速度快,能檢測待檢測管材的表麵及亞表麵,且不受待(dài)檢測方管(guǎn)表麵油汙等雜質的影響。缺點是(shì)易將非缺陷結構判定為缺陷(xiàn),誤(wù)檢率較(jiào)高,檢(jiǎn)測分辨率不容易調整(zhěng)。

There

are five main methods to detect the surface defects of square tubes: one is eddy

current testing. Eddy current testing has many forms, such as conventional eddy

current testing, far-field eddy current testing, multi-frequency eddy current

testing and pulse eddy current testing. Using eddy current sensors to induce

metal, different types and shapes of defects on square tubes surface will

produce different types of signals. It has the advantages of high detection

accuracy, high detection sensitivity, fast detection speed, can detect the

surface and sub-surface of the pipe to be tested, and is not affected by the

impurities such as oil contamination on the surface of the square pipe to be

tested. The disadvantage is that it is easy to judge the non-defective structure

as a defect, the false detection rate is high, and the detection resolution is

not easy to adjust. 二超聲波檢測

Two-Ultrasound Detection

利(lì)用超聲波進入物體遇到缺陷時,一部分聲波會產生反射,發射(shè)和接(jiē)收器可對反射波(bō)進行分析,就能異(yì)常精確地測出缺陷來。超聲波檢測常用於鍛件(jiàn)檢測,檢測探傷靈敏度高,但(dàn)是不易檢查形狀(zhuàng)複雜的管材,要求被檢查的方管表麵有一定光潔度,並需有耦合(hé)劑充填滿探頭和被檢查表麵之間的空隙。

When

ultrasound enters an object and encounters a defect, a part of the acoustic wave

will produce reflection. The transmitter and receiver can analyze the reflected

wave, and the defect can be detected abnormally and accurately. Ultrasound

detection is often used for forging detection, which has high detection

sensitivity, but it is not easy to inspect the pipe with complex shape. It

requires that the surface of the inspected square pipe should have a certain

degree of smoothness, and the coupling agent should be used to fill the gap

between the probe and the inspected surface.

三磁粉法檢測

Detection by three magnetic powder method

磁粉法檢測的原理是在方管材料中實現磁場,根據缺陷處的漏磁場(chǎng)與磁粉的相(xiàng)互作(zuò)用,當(dāng)表麵和近表(biǎo)麵有不連續(xù)或缺陷時,則在不連續處或缺陷處磁力線(xiàn)發生局部畸變產生磁極。其優點是設備投資少,可靠性(xìng)高,具有(yǒu)直觀性。缺點是操作成本高,不能對缺陷準確分類,檢測速度較低。

The

principle of magnetic particle method is to realize magnetic field in square

tube material. According to the interaction between leakage magnetic field at

defect and magnetic particle, when there is discontinuity or defect on surface

or near surface, the magnetic line at discontinuity or defect will distort

locally to produce magnetic pole. Its advantages are less investment in

equipment, high reliability and intuition. The disadvantage is that the

operation cost is high, the defect can not be accurately classified, and the

detection speed is low.

四紅外線檢測

Four Infrared Detection

通過高頻感應線圈,在方管表麵產生感應電流,感應電流會導致缺陷(xiàn)區域消耗更多電能,引起局部溫度升高,通(tōng)過紅外線檢測局部溫度,從而(ér)確定缺陷深度。紅外線檢測一般用於平直表麵的缺陷檢(jiǎn)測,不適合檢測表麵不平整金屬。

Through

high frequency induction coil, induction current is generated on the surface of

square tube. Induction current will cause more electric energy to be consumed in

defect area, causing local temperature to rise. The defect depth can be

determined by infrared detection of local temperature. Infrared detection is

generally used for flattening surface defect detection, not suitable for

detecting surface irregularity metal.

五漏磁(cí)檢測

Five magnetic flux leakage detection

方(fāng)管的漏磁檢測方法和磁(cí)粉(fěn)檢測方法非常相似,適用範圍、靈敏度和可靠性較磁粉檢測方法(fǎ)更(gèng)強。

The magnetic flux leakage

testing method of square tube is very similar to that of magnetic powder testing

method, and its application scope, sensitivity and reliability are stronger than

that of magnetic powder testing method.